VICTORIA -- At the University of Victoria (UVic), a team of researchers say the next frontier of COVID-19 testing could be found when our toilets flush.

Three UVic engineering experts have partnered with a local tech firm to develop a sewage monitoring system that could detect community outbreaks of the coronavirus.

"We can monitor on a community level the presence of COVID in the population at a much easier, and often at an early warning time, than you can from samples coming from individuals," said engineering researcher, Heather Buckley.

According to UVic, wastewater samples can analyse COVID-19 on a city or regional level.

Individual tests are most often administered when a person shows symptoms, but according to the team behind the sewage testing, their work could discover the level of asymptomatic individuals in the community who don’t even know they are carriers.

“It doesn’t tell us that an individual is experiencing COVID-19, but it does tell us that it’s coming back into the population,” said Buckley.

Tech firm Pani Energy Inc. and the UVic engineers have been given the green light to start testing in the Greater Victoria area this month.

They hope to expand the work to other Canadian health regions soon.

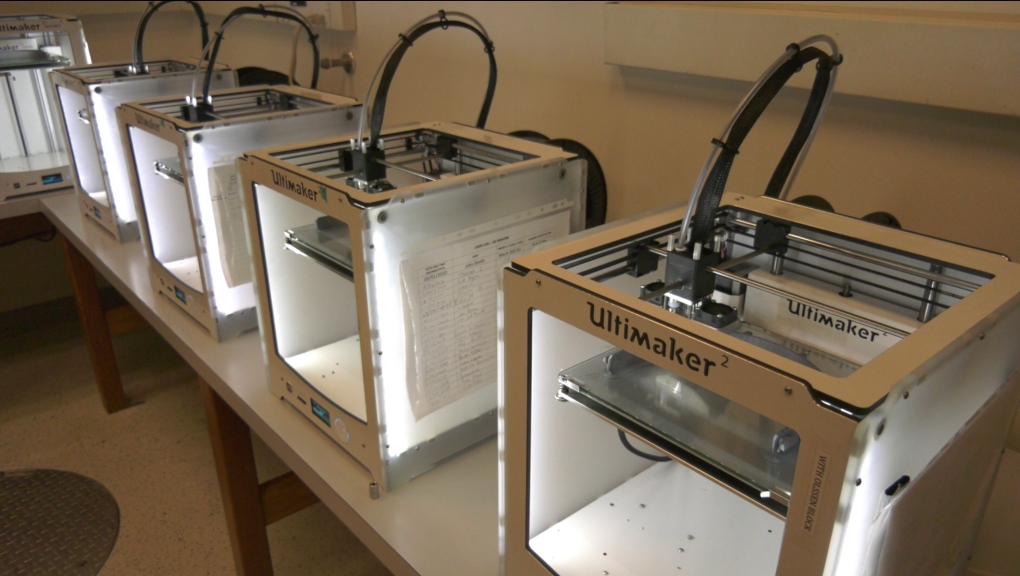

Across the Capital Region inside Camosun College’s Innovation Lab another new move is about to impact the local COVID-19 response.

Camosun tells CTV news they have developed a new way to create plastic face shields for front line health-care workers.

"We are doing this entirely for the next wave of the pandemic,” said director of innovation, Richard Gale.

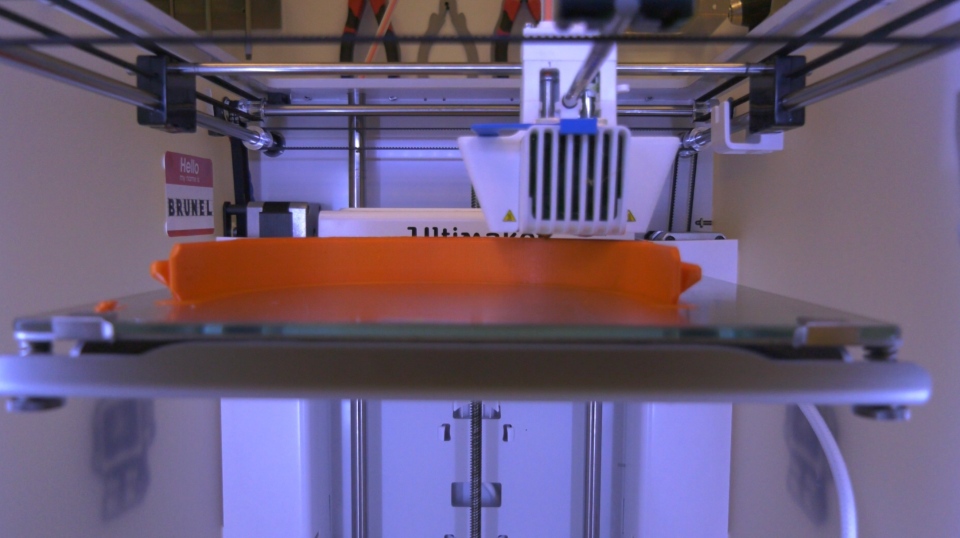

Camosun has been on the forefront of designing 3D-printed personal protective equipment since the pandemic began.

The school itself has printed thousands of face shields for Island Health workers, and has also partnered with a local plastics company to keep production going on a mass scale.

Now, the school and AP Plastics Inc. have been given a $75,000 grant to move forward with plans to manufacture cheaper and more effective shields.

“They are going to be entirely injection molded,” Gale told CTV News.

“With one continuous stream of plastic we can create the shields much faster and cheaper.”

Gale said he hopes to start creating the one-piece shields by the end of August.